Foshan Nijia Gas Factory Safety Production Supervision Construction Project

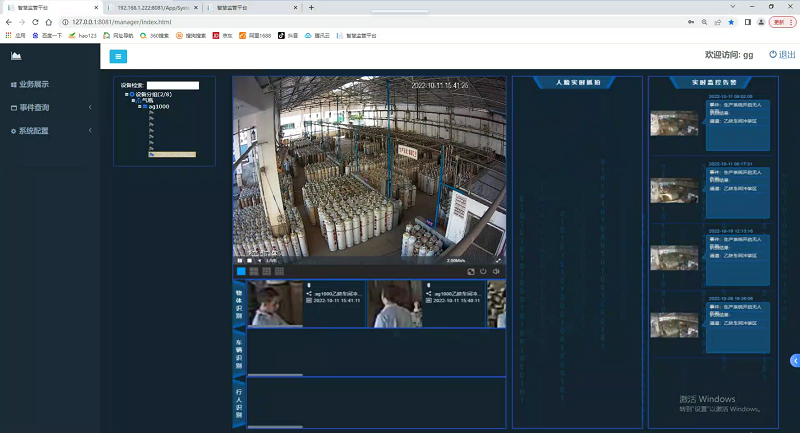

Due to the high uncertainty in the arrangement of workshop production,the existing system needs to be activated and deactivated within specific time periods according to actual demand to prevent the omission and false reporting of monitoring events.However,the on-site server side of the factory area is often unattended,which makes it difficult to observe the systems situation in real time.To prevent delays in obtaining alarm information,the factory area needs to adopt an alarm method that can directly push alerts to the relevant responsible persons.

First,lets delve into why it is necessary for the factory area to activate and deactivate the system within specific time periods according to actual demand.This is because during the production process,the gas composition and concentration in the workshop environment may change,and these changes could trigger alarms from the monitoring equipment.If the system is not activated and deactivated within specific time periods,these changes might be overlooked,leading to the omission of monitoring events.On the other hand,if the system is activated when it should not be,it could lead to false alarms,causing disruptions and annoyances in the production process.

However,since the on-site server side is often unattended,traditional alarm methods cannot ensure that relevant responsible persons can obtain information in a timely manner when the system triggers an alarm.This can result in delayed acquisition of alarm information,potentially delaying adjustments and control of the production process,and thereby increasing production risks.

To address this issue,the factory area needs to adopt a new alarm method,one that directly pushes alarms to the relevant responsible persons.This method has the following advantagesfirst,it ensures the timeliness of alarm information,allowing relevant responsible persons to understand the systems situation at the earliest time,thereby enabling a rapid response;second,it improves the targeting of alarms,as each responsible person will receive alarms related to their own responsibilities,which helps to increase the efficiency of production management;finally,it also enhances the reliability of alarms,as responsible persons can directly review system data,thus being able to more accurately judge the authenticity of the alarms.

Foshans Nijia Gas Factory has adopted an alarm notification method that directly pushes alerts to the relevant responsible persons as an effective solution in the face of uncertainties in workshop production arrangements.This approach not only ensures the timeliness and targeting of alarms but also enhances the efficiency and reliability of production management,thereby reducing production risks.The factory should actively explore and implement this alarm notification method to ensure smooth production processes.

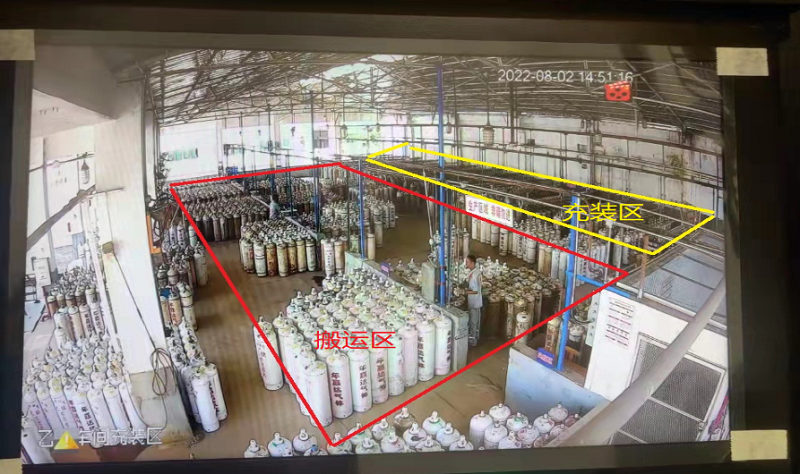

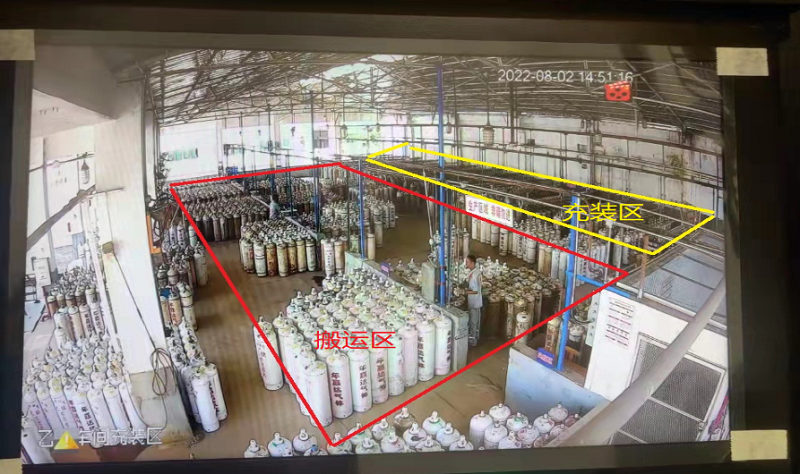

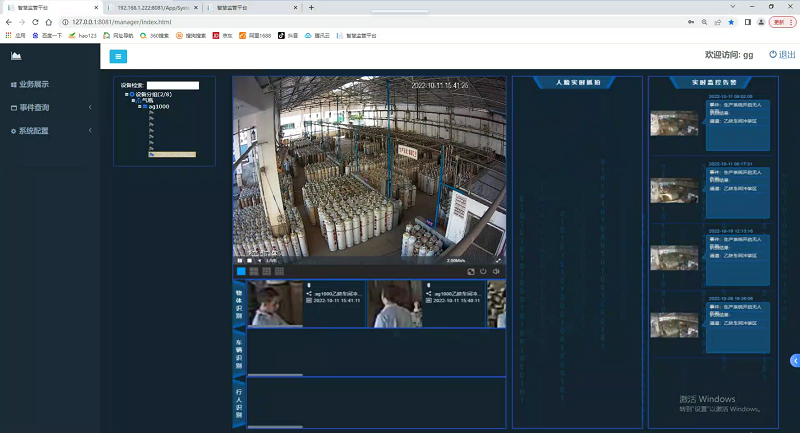

System Layout

The factory area currently only needs to connect one video route from the acetylene workshop.In the future,the factory may expand to add two more monitoring routes in other workshops to check the attendance of personnel on duty.A single LX-AG1000 intelligent gateway is planned to be installed inside the factorys machine room cabinet,accessing the camera video streams through the switch.The system is designed to be locally deployed,with factory computers providing remote operation services.

Hanyang District Water Bureau Emb...

Hanyang District Water Bureau Emb... NO

NO