Solutions

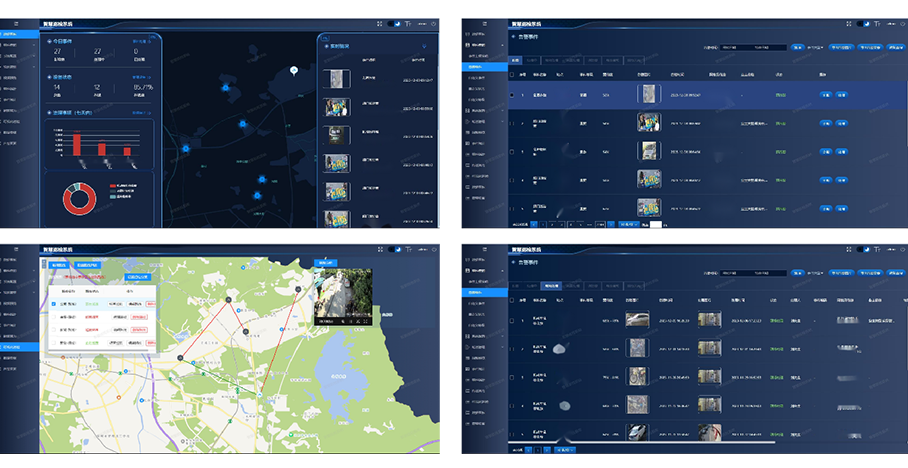

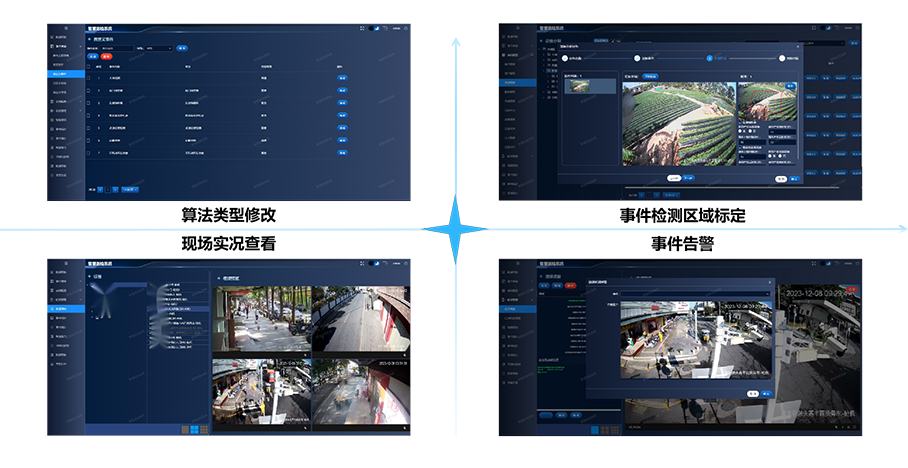

Intelligent Park Safety Supervision Solution

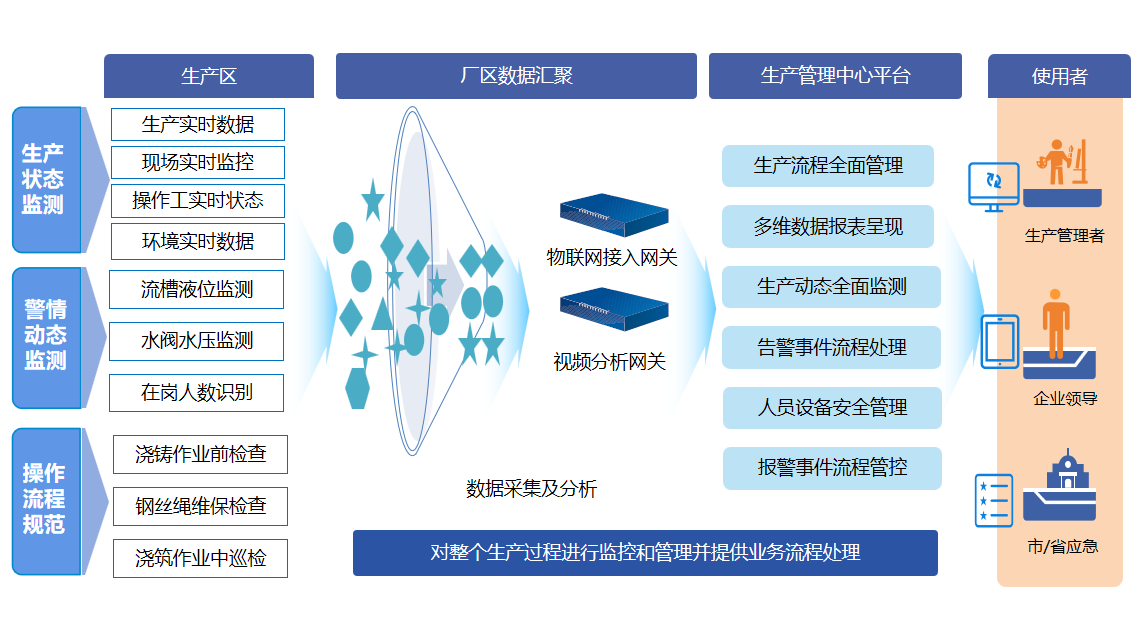

Digital Solution for Safe Production in Aluminum Processing (Deep Well Casting)

Digital solutions for safety production in metallurgical manufacturing.

Digital Solutions for Safety Production in Steel Manufacturing

Intelligent Patrol Inspection System Solution